Bright Dental Lab has been using CAD/CAM technology for fabricating dental lab works over 10 years.

We have a CAD/CAM team to work on this aspect.

CAD/CAM has provided dentists and dental laboratories with the opportunity for collaboration on the fabrication and delivery of crowns, without the use of either traditional impressions or models. Inherently, this is a game changer that can be viewed from several perspectives.

Traditionally, impressions were taken and a model was either poured and trimmed in the lab area at the back of the dental office or sent to the laboratory for pouring. Impression materials must be of high quality, the actual impression taken requires expertise, and the impression must be properly treated/stored/shipped. Flaws found in impressions include voids due to the incorporation of bubbles or contamination, tears associated with undercuts, shrinkage due to drying or high temperatures, and margins missing due to incorrect isolation or lack of flow of the material around the margins of the prep. These pitfalls can be avoided with careful technique, use of a quality impression material, and proper handling. Potential flaws also include those associated with the pouring of the model – such as air voids and lack of detail due to poor reach of the stone into the model prior to setting (for instance, if a vibrator is not used to encourage flow of the stone material into all detailed areas of the impression).

Further considerations include the need for dies when fabricating indirect restorations from models as well as the potential for abrasion or damage to models, which may result in over-sized or poor contacts, occlusion and intaglio dimensional inaccuracies. Infection control is also an essential component in the handling of traditional impressions. The impression must first be rinsed to remove saliva, blood and any other debris present, and then disinfected in accordance with the impression material manufacturer’s instructions before being dried, then shipped or poured. With CAD/CAM scanning, the scanner itself must be treated appropriately as recommended by the manufacturer.

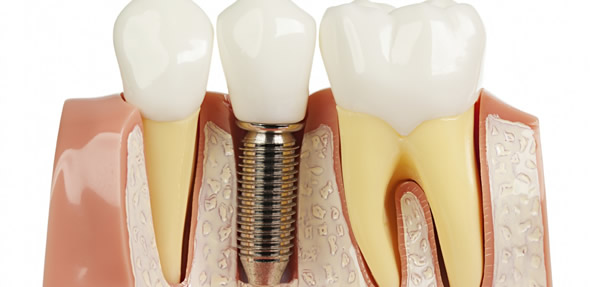

There is no risk of material-related flaws with digital impressions. Provided tissue retraction (if required) and isolation are used, and the scan is properly executed and captured, the impression will be accurate. Model-free crowns remove the need for a poured or milled model, and speed up fabrication. CAD/CAM still permits milling of resin-based models if traditional fabrication of a crown is preferred or if the laboratory and dental office would like to check the fit of a milled crown on a model. In either case, the potential for error associated with stone models is avoided.

Increasingly, CAD/CAM model-free crowns are being fabricated, i.e., without the use of a milled model even for checking the contact and occlusions. Virtual articulators are used while designing the crown, and they result in an accurate and suitable crown occlusal form.

For solid zirconia crowns,we are very experienced in this work,

Welcome our doctors have a try our lab,we will provide the lab works you demanded to you.

Thank you for your read.